For years I have heard that senior Toyota leaders who retired or left to advise other companies spent a lot of time on 5S, which made no sense. After all, 5S is basically cleaning up the place. Most companies start with “sort” to get rid of stuff they do not need, “set it in order” what they did need, label places to “standardize,” “sweep up,” and struggle to “sustain.” Therefore the exercise needs to be repeated periodically, like the annual spring cleaning.

Recently I revisited Avanzar, Toyota’s interior and seating supplier for their San Antonio, Texas truck plant. Most major suppliers are on-site delivering directly to the factory which in the case of seat assembly is right across a wall. Avanzar’s CEO, Heriberto (Berto) Guerra, was very excited about their Japanese advisor, formerly of Toyota, and all he had been teaching them about real kanban. I had visited a year earlier and Mr. Guerra was very excited about their Japanese advisor, formerly of Toyota, who was teaching them kanban. A year before that, he said they were making progress in a few model areas and now there was kanban everywhere. Mr. Guerra also raved about the way their advisor was teaching them 5S, which again I found confusing.

Avanzar’s assembles seats in sequence with the trucks they will be in and has a 90 minute window between building installation in the truck (sometimes only 60 minutes.). There is little margin for error so Avanzar held 3-5 days of component parts inventory. There Japanese advisor wanted them to go to 2 hours for local parts. To begin with, however, he said they could keep safety stock on high-level shelves, and the two hour supply would be kept in lower, easy to reach shelves.

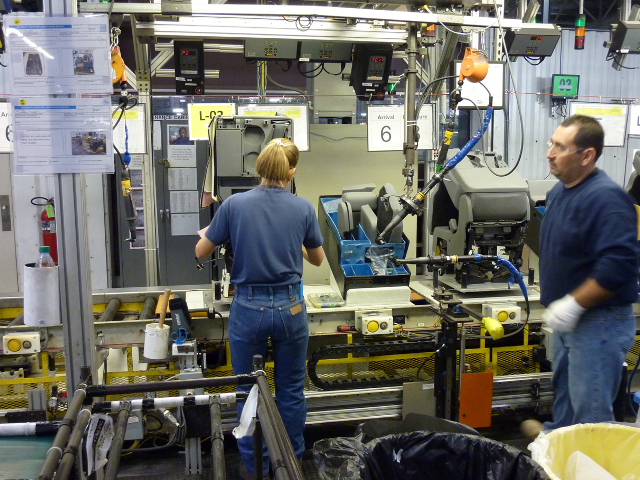

Kitted parts for seat assembly. Photos courtesy of author

Mr. Guerra also showed me a model area in which parts for seat assembly were kitted on racks (see photo above) and the assemblers could get all their parts for one seat from one set up, so parts were easy to reach. This improved productivity and quality and reduced unsafe bending. The line became cleaner as the large bins of parts were gone, and it was much easier to adjust to changes in line speed (the element of takt). Of course some of the labor was shifted back to a kitting area, but that was being reduced over time through kaizen.

What shocked me is that Mr. Guerra described everything I saw as part of 5S. He said for the last 1 ½ years their advisor would not let them go beyond the first “S” and this was all part of that. I was shocked. Mr. Guerra further explained that the first S was “scrap and separate.” They were getting rid of what they did not need by reorganizing the flow of materials. They were separating what they really needed for production by organizing the 2 hours of inventory on low shelves and the safety stock on higher shelves, and separating what the operator really needed in the kits from what they did not yet need in the kitting area. I completely changed my paradigm of 5S that day. Properly used, it was a tool for flow, quality, productivity, and safety.

Dr. Jeffrey Liker is professor of industrial and operations engineering at the University of Michigan and author of The Toyota Way. He leads Liker Lean Advisors, LLC and his latest book (with Gary Convis) is The Toyota Way to Lean Leadership.